Choosing the right Actuator

TecHome offers a range of Linear Actuators. An actuator can be used for either pushing or pulling with the ability to lift weights of up to 1631kg, no hoses or pumps are needed for the operation of an electric linear actuator, unlike hydraulic and pneumatic systems, resulting in a product that’s easy to install with little or no maintenance required.

Actuators require both a control mechanism and an energy supply. Typically, the control device is a valve. The valve requires a low-energy signal to activate. It can be activated with electrical voltage, pneumatic or hydraulic fluid pressure, or even by human force. Electric current, hydraulic pressure, or pneumatic pressure are also potential energy supplies.

TecHome’s ranges of Actuators have been carefully selected to offer you the best quality at the most competitive price. We offer an extensive range of linear actuators (including water resistant and weatherproof versions) with many additional features to suit your application. In addition to our actuators, we offer a huge range of accessories such as; electronic motor controllers, remote controls and rain sensors.

Use these 8 Steps to Choose the Right Actuator for Your Application

Various actuators are used in multiple industries, with so many different actuators available, it is important to find the right actuator for the task required. Here is a brief guide to choosing the best.

1. Determine the Type of Movement Needed

You’ll be able to see if the function calls for decisive linear motions or if additional dynamism is needed in the final function, depending on the function. But you might also want to think about how far you want that movement to go.

2. Considerations for Energy Input

Electrical actuators are widely used and can perform a more comprehensive range of tasks. However, in cases where the required electrical current is not always feasible, you can use hydraulic and pneumatic actuators to do away with the requirement for high voltage input.

3. Precision

According to a “general” rule, smaller, more detailed, and delicate jobs, including selecting and handling, need more accuracy. In contrast, heavy-duty labor may get by without it. That factor will substantially influence the actuator you choose.

4. What Force is Best

The main goal of an actuator is to move anything; however, the amount of force needed varies according to how heavy or oversized the item is. Consider the sizes of the things your actuator needs to move when selecting one with a sufficient load capacity.

5. How Much Room is There for Movement?

Any actuator will have a stroke length, which you should consider when selecting one for your intended use.

6. What Speed Are You Looking For?

The speed of the actuator is a significant factor because actuators requiring more force are frequently slower than those generating less force.

7. What is the Operational Environment?

Both industrial applications and the more structured settings of interior labs and workshops regularly utilize actuators.

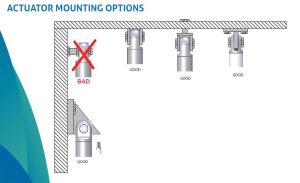

8. How Will it be Mounted?

There are several mounting options for actuators. A dual-pivot mounting mechanism, for instance, enables the item to rotate or swivel while extending and retracting. The actuator is kept in position more securely with a fixed mounting mechanism.

Our Actuators

Some of our best-selling actuators are:

TA2 Series Linear Actuator

The compact-size TA2 linear actuator is perfect for use in small spaces without sacrificing force or capability. The TA2 is a smaller version of the higher-powered TA2-P series linear actuator.

MA2 Series Linear Actuator

The MA2 series linear actuator was specifically designed for applications that face harsh working environments and require ruggedness and durability. Its IP69K protection ensures it will withstand high temperatures, high-pressure water jets, and the ingress of dust and other solid contaminants. The MA2 also has optional Reed switches along the outer tube that allow users to adjust the stroke length. For improved control and accuracy of motion, the MA2 can be customized with many different feedback options depending on your application requirements.

JP Series Linear Actuator

The JP4 in-line linear actuator is best suited to applications that require compact installation size without sacrificing load and speed. The JP4 is often used in opening window and louvre applications.

Check out this video of our JP4 in action.

- Mar 2019

- Jun 2019

- Jul 2019

- Oct 2019

- Feb 2020

- Mar 2021

- Jul 2021

- Sep 2021

- Oct 2021

- Nov 2021

- Jan 2022

- Feb 2022

- Mar 2022

- Apr 2022

- May 2022

- Jul 2022

- Sep 2022

- Oct 2022

- Nov 2022

- Dec 2022

- Jan 2023

- Feb 2023

- Mar 2023

- Apr 2023

- May 2023

- Jun 2023

- Aug 2023

- Oct 2023

- Jan 2024

- Feb 2024

- Apr 2024

- May 2024

- Jun 2024

- Jul 2024

- Aug 2024

- Sep 2024

- Oct 2024