What Is Dual Synchronisation and Why Do I Need It?

More than likely, you won’t often find yourself in a position where you require more than one actuator, but if your application does require two actuators (due to things like a need for excess force, or mitigating sideways movement), you need to ensure that the two actuators are synchronised.

What is motor synchronisation?

Slight variation between the actuator productions results in them operating at slightly different speeds; this can have a number of negative impacts on both the application and actuator.

Motor synchronisation keeps actuators moving at the exact same speed. This allows you a high level of control, and ensures equal load distribution. In turn, synchronisation protects the actuator and the application.

How does synchronisation work?

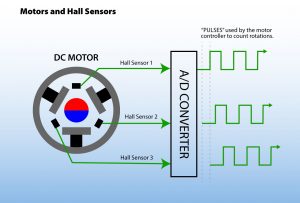

Synchronisation is achieved through the use of a Hall Effect Sensor. The “Hall Effect” occurs when a voltage difference is created in the conductor through the application of a magnetic field perpendicular electric current flow.

The voltage difference can be measured with a Hall Effect Sensor, which outputs a series of “pulses” that translate to the rate at which the motor is spinning. Next, the pulses are read by a dual synchronised motor controller, which distributes variable voltages between the actuators to ensure they are traveling at the same rate.

When should you use synchronisation?

There are three main situations in which you should use a Hall Effect Sensor.

-

Extra force

One common reason you may need to utilise synchronisation is that you require more force than a single actuator is capable of producing.

For example, if you need to lift a 180 kg object but you only have 100 kg actuators, you can use dual synchronisation to achieve a combined force of 200 kg.

-

Stabilisation

If not for extra force, you’ll likely turn to synchronisation for added stability. When mounting on two sides of an object, synchronisation removes any concern over side-force on the actuator.

For example, if you need to open a large window, the most effective method is to mount the actuators to the sides; both actuators must work in synchronisation to ensure there’s no flex or side movement to the glass.

-

Electronic limits and fine motor control

On single actuator applications, Hall Sensors can impose electronic limit-ends with specific motor controllers.

For example, if your application requires 130 mm but you only have 150 mm actuators available, you can program controllers (such as TH717) to stop the actuator at a specific location (measured in pulses), or even default the actuator to a location along its complete stroke length.

Does your application require synchronisation or hall sensing capabilities?

If you’re convinced that your application calls for synchronisation or hall sensing, TecHome’s TH717+ Smart Controller is the solution you need.

The TH717+ is TecHome’s latest and most advanced motor controller available; it’s capable of synchronisation, hall sensing control, RF remote, and Bluetooth control.

Looking for more information on the TH717+ or just want some extra insight about whether or not your application requires synchronisation? Get in touch with TecHome today!

- Mar 2019

- Jun 2019

- Jul 2019

- Oct 2019

- Feb 2020

- Mar 2021

- Jul 2021

- Sep 2021

- Oct 2021

- Nov 2021

- Jan 2022

- Feb 2022

- Mar 2022

- Apr 2022

- May 2022

- Jul 2022

- Sep 2022

- Oct 2022

- Nov 2022

- Dec 2022

- Jan 2023

- Feb 2023

- Mar 2023

- Apr 2023

- May 2023

- Jun 2023

- Aug 2023

- Oct 2023

- Jan 2024

- Feb 2024

- Apr 2024

- May 2024

- Jun 2024

- Jul 2024

- Aug 2024

- Sep 2024

- Oct 2024